Guide to Automotive labels for Under The Hood

Your expectations must remain high when searching for the solutions you need for under the hood automotive labels. However, when you face challenges and need a new label solution, you look at multiple factors:

- Abrasion and overall high durability resistance, as these labels are sometimes exposed to maintenance technicians and could be subject to rougher handling.

- Chemical resistance, as vehicles are exposed to coolants and oils needed

- longevity requirements; given the average life span of a car is roughly 200,000 miles, you need them to last

- Safety color requirements; you may need red or yellow warning labels to include these colors.

- High and low temperature resistance when the engine is hot or when parked in warmer or cooler climates

- and more

Motor vehicle under the hood label solutions

A valuable solution will be needed, and thermal transfer ribbons can cover any print requirements. Although, luckily, resin thermal ribbons are formulated and designed with automotive labels in mind, made to last and withstand nearly any elements that your labels are exposed to.

When implementing the correct thermal ribbon and label stock combination, you must keep certain things in mind. First, the label text and image must remain crisp and easily legible throughout its 12+ yearlong lifespan. Second, your label stock will also need to have resistance to elements such as temperature and have the ability to stick to multiple types of surfaces such as metal and plastics.

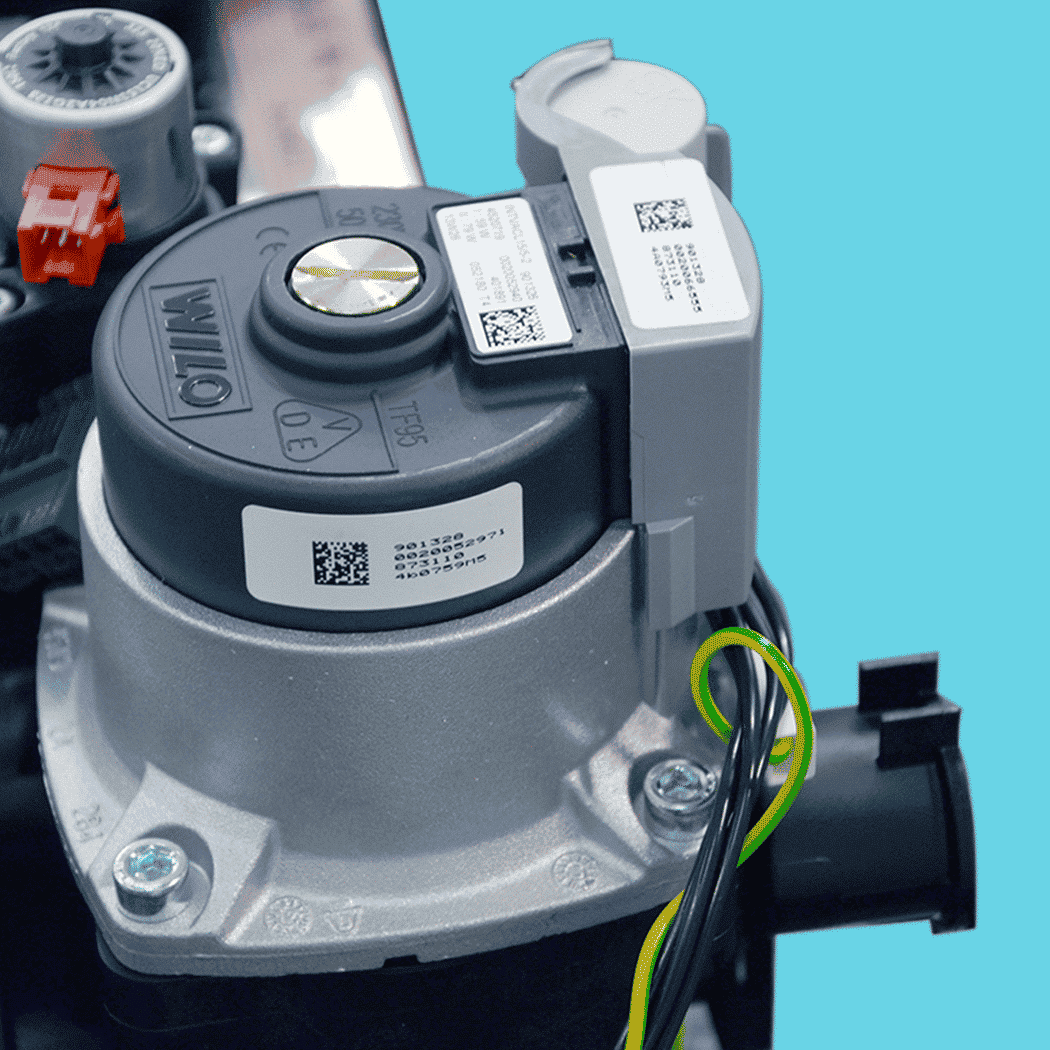

Examples of types of labels and applications may include:

Labels

- GHS hazard pictograms – Smaller printed symbols & characters

- Caution single word labels – Noting words like warning or danger

- Identification labels and barcodes

- Federal safety certification labels

- Emission labels (Vehicle emissions control information label – required)

- Includes the engine size

- A 12-digit engine identification number

- Service part labels

- And more

Applications

- Batteries

- Engine components

- Air conditioning compressors

- Spark plugs

- Air filters

Why using thermal transfer technology for this application ?

ARMOR-IIMAK thermal transfer ribbons can provide you with the most durable and reliable solution for your under the hood automotive labeling needs. Meeting all requirements in fulfilling the print quality, color density and lifespan of legibility.

For this application, we recommend the following products: